Wonder material Graphene could revolutionise the construction industry

Scientists say a greener, stronger and more durable concrete made using “wonder-material” graphene could revolutionise the construction industry.

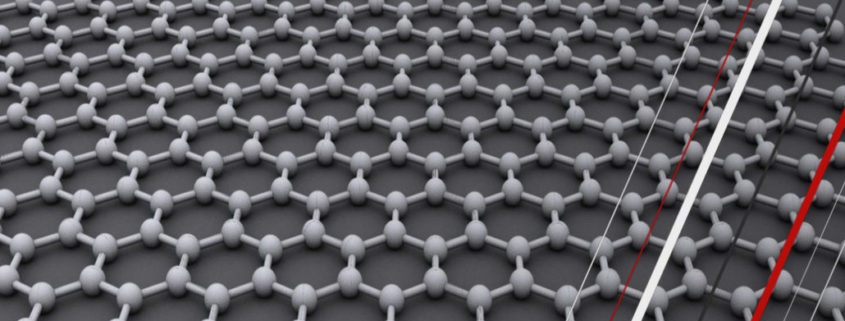

Graphene is a form of carbon first reliably produced at the University of Manchester by researchers in 2004, work which led to two Nobel prizes. It is made up of a single layer of carbon atoms in a hexagonal lattice. Its structure gives it important physical qualities, including efficient conductance of heat and electricity and unusual strength.

A research team at the University of Exeter, which includes Cast Consultancy’s Dimitar Dimov, has developed a technique which uses nanoengineering technology to incorporate graphene into traditional concrete production.

The researchers say the new composite material is more than twice as strong and four times more water resistant than existing concretes, and has been tested using British and European industry standards.

The graphene-reinforced concentre material also reduces the carbon footprint of conventional concrete production methods, according to the University of Exeter scientists. They add that the technique could pave the way for other nanomaterials to be incorporated into concrete.

Dimitar Dimov, lead author, who works at the University of Exeter engineering department and with construction consultancy Cast, said: “This research is important as it can be applied to large-scale manufacturing and construction. The industry has to be modernised by incorporating not only offsite manufacturing, but innovative new materials as well.

“Finding greener ways to build is a crucial step forward in reducing carbon emissions around the world and so help protect our environment as much as possible. It is the first step, but a crucial step in the right direction to make a more sustainable construction industry for the future.”

Professor Monica Craciun, co-author of the paper and also from Exeter’s engineering department, said: “This new composite material is an absolute game-changer in terms of reinforcing traditional concrete to meets these needs. Not only is it stronger and more durable, but it is also more resistant to water, making it uniquely suitable for construction in areas which require maintenance work and are difficult to be accessed.

“Yet perhaps more importantly, by including graphene we can reduce the amount of materials required to make concrete by around 50% – leading to a significant reduction of 446kg per tonne of the carbon emissions.”

The paper, Ultrahigh Performance nanoengineered Graphene-Concrete Composites for Multifunctional Applications, is published in the journal Advanced Functional Materials.

The research was supported by the UK’s Engineering and Physical Sciences Research Council.

Cement-making accounts for 6% of global carbon emissions, and manufacturers must make sharp reductions if the Paris climate goals are to be met, according to the Carbon Disclosure Project, in a recent study.

Source: Construction Manager / The Guardian

Leave a Reply

Want to join the discussion?Feel free to contribute!