Can a building be net zero carbon?

Following on from our post last month about COP27, and the growing importance of sustainability in the construction industry, zero carbon is also something that is increasingly in the news.

A panel has been put together to determine exactly what constitutes a net zero carbon building and is now calling for evidence.

The NZCBS is the UK’s first Net Zero Carbon Buildings Standard and are championing the initiative.

We are calling on UK built environment industry practitioners to share embodied carbon and in-use operational energy performance data for their buildings.

To develop the Standard, benchmarks will be agreed for the operational energy usage and embodied carbon performance levels today, and limits and targets will be set out for future years based on the industry’s required decarbonisation trajectory. To do this, the project is seeking case study data from the real estate and built environment industry.

The deadline for submission is the 16th December.

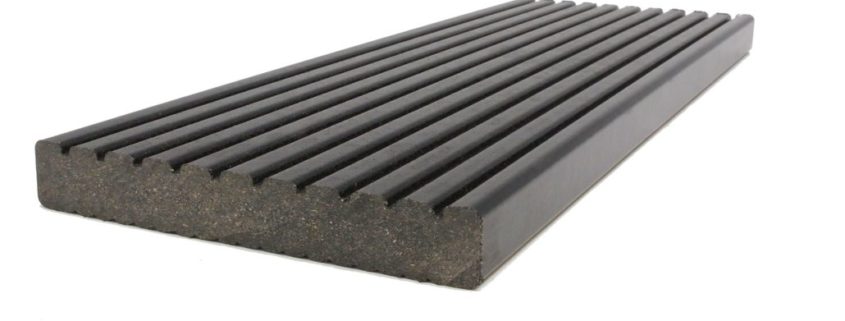

The Standard will set out metrics by which net zero carbon performance is evaluated, as well as performance targets, or limits, that need to be met. These are likely to include energy use, upfront embodied carbon, and lifecycle embodied carbon, with other metrics – such as space heating/cooling demand and peak load – also to be considered. It will also cover the approach to carbon accounting, procuring renewable energy, and the treatment of residual emissions, including carbon ‘offsetting’. However, the scope and output of the Standard may evolve throughout the development process.

It is expected that claims will be required to be validated based on in-use measured data and interim verification of an asset at design stage or once the asset is built but not yet operating may also be considered.

The output will be for developers, contractors, asset owners and managers, occupiers, investors, financiers and funders, consultants, building industry professionals, building managers and product/material manufacturers, suppliers, and distributors. It is for anyone who wants to either fund, procure, design, or specify a Net Zero Carbon Building and anyone wanting to demonstrate that their building is ‘Net Zero’-aligned with an industry-agreed Standard.

Performance targets will align with science-based trajectories needed to achieve net zero by 2050 and a 78% reduction by 2035 in the UK, i.e. what is known to be required to stand a reasonable chance of mitigating global warming to 1.5°C. It will also align with the energy demand reductions projected to be required to enable a net zero carbon energy supply sector.

The approach will be applicable to both existing and new buildings (e.g. Homes, Offices, Education, Industry, Retail, Hotels, Healthcare etc.). To start, the focus will be on the most common building typologies, especially those for which industry stakeholders have already robust performance data available to inform the setting of performance targets. The Standard will not apply to infrastructure.

The project will hopefully launch in May.

So, what actually is a net carbon building?

A carbon neutral building is one where the design, construction, and operations do not contribute to emissions of greenhouse gases that cause climate change. Reducing harmful greenhouse gas emissions from the building sector will greatly help meet climate goals.

In the short and medium term the national grid will not be fully decarbonised and so buildings will need to make use of carbon offsetting to achieve a net zero carbon balance.

Sources: NZC Buildings / net zero carbon guide