Ekodek Board System

Ecodek have been producing their unique ecodek® WPC board system for over 14 years. In 2018, the production of ecodek® material consumed more than 3600 tonnes of recycled plastic milk bottles and sustainably sourced hardwood fibres.

With the versatility to adapt to urban or traditional design schemes, ecodek® will allow the designer to transform outdoor spaces and gardens into feature areas. They have produced a range of specific screws, substructure bearers and beams specifically designed for their boards.

ecodek® can be found across the UK and beyond, in residential settings and in public realm areas such as balconies, roof terraces, walkways, bridges, schools, care homes, stadia and restaurants.

Offering bespoke lengths to suit individual projects means a welcome relief on site to the usual problem of waste materials. ecodek® material is 100% recyclable, should any waste be generated on site, their buy back scheme means that this can be sent back to the factory and put back into the production of new boards.

The boards will not warp, splinter or rot, and as ecodek® does not promote mould or algae growth, only require minimal maintenance, and do not require sanding or sealing.

ecodek® material comes with a 25 year warranty as standard, giving piece of mind to both specifier and end user.

Here’s a re-cap of the benefits of ecodek® boards over traditional timber decking:

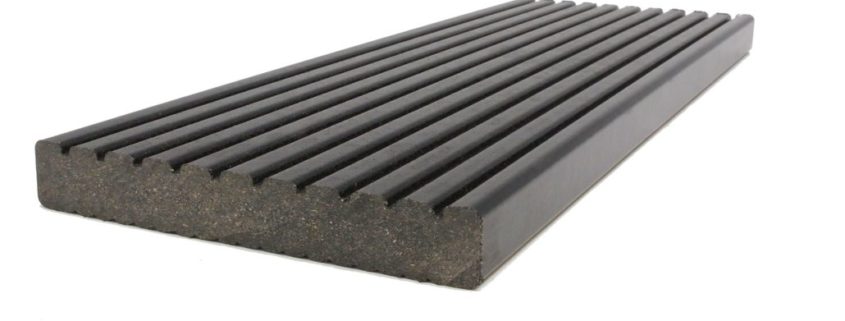

- High quality, British made Wood Plastic Composite

- ecodek® contains 95% recycled and sustainably raw materials and is 100% recyclable

- Low maintenance – doesn’t require sanding or staining

- Solid profile that is resistant to rotting, algae and fungal growth plus, no splintering, splitting or flaking

- Low potential for slip in both wet and dry (tested to HSE standards)

- Bespoke lengths

- Easy as timber to work with

- Low moisture absorption

- In-built termite and UV resistance

- Carbon negative production

- 25 year warranty

Source: UK Construction Week

Leave a Reply

Want to join the discussion?Feel free to contribute!